Cleaning ,Disinfecting, Sanitation And Everything In Between Guide

Understanding the differences between cleaning, disinfecting, and sanitizing is crucial across various industries. From healthcare facilities to food processing plants, each process serves a specific purpose in maintaining safety standards. This comprehensive guide explores the science behind these practices, proper techniques, and industry-specific requirements to ensure optimal cleanliness and compliance.

The maintenance of clean, disinfected, and sanitized environments is fundamental across numerous sectors, from healthcare facilities to food processing plants. While these terms are often used interchangeably, they represent distinct processes with specific purposes and outcomes. Cleaning removes visible soil and contaminants, disinfecting kills pathogens on surfaces, and sanitizing reduces microorganisms to levels considered safe by public health standards. Understanding these differences is essential for implementing effective protocols that protect public health and ensure regulatory compliance.

Understanding Cleaning, Disinfecting, and Sanitizing

Cleaning is the first step in any hygiene protocol, involving the physical removal of dirt, debris, and some microorganisms from surfaces using soap or detergent and water. This process doesn’t necessarily kill germs but reduces their numbers by removing the medium they need to survive and multiply. Disinfection follows cleaning and uses chemicals to kill pathogens on surfaces, significantly reducing infection risk. Sanitizing, meanwhile, lowers the number of microorganisms to levels considered safe according to public health standards—a middle ground between cleaning and disinfecting that’s particularly important in food service environments.

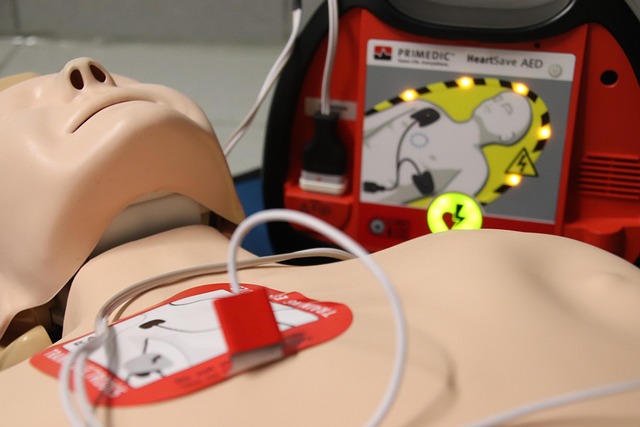

Cleaning and Disinfecting Medical Equipment

Medical equipment requires specialized cleaning and disinfection protocols to prevent healthcare-associated infections. These items are categorized by risk level: critical items that enter sterile tissue require sterilization; semi-critical items contacting mucous membranes need high-level disinfection; and non-critical items touching intact skin can undergo low-level disinfection. Healthcare facilities must follow manufacturer guidelines and regulatory standards for each device. Common disinfectants include hydrogen peroxide, quaternary ammonium compounds, and alcohol-based solutions, each with specific contact times and compatibility considerations. Documentation of all cleaning and disinfection procedures is essential for quality assurance and regulatory compliance.

Cleaning and Disinfection of Patient Care Equipment

Patient care equipment presents unique challenges due to frequent handling and exposure to potentially infectious materials. Items like blood pressure cuffs, stethoscopes, and wheelchairs require regular disinfection between patient uses. Effective protocols include clear responsibility assignments, appropriate personal protective equipment (PPE), and validated disinfection methods for different equipment types. Electronic devices need special consideration, using compatible disinfectants that won’t damage sensitive components. Training healthcare personnel in proper techniques is crucial, emphasizing thoroughness and attention to high-touch surfaces. Regular audits and compliance monitoring help identify gaps in procedures and reduce healthcare-associated infection risks.

Cleaning and Sanitation Procedures in Food Industry

The food industry follows rigorous cleaning and sanitation procedures governed by HACCP (Hazard Analysis Critical Control Points) principles. These protocols involve a systematic approach: pre-cleaning to remove large debris, cleaning with appropriate detergents, rinsing to remove chemical residues, sanitizing to reduce microorganisms to safe levels, and final rinsing when required. Different areas within food processing facilities require specialized approaches, with food-contact surfaces receiving the most stringent treatment. Environmental monitoring programs verify sanitation effectiveness through microbial testing and ATP (adenosine triphosphate) detection. Documentation of all procedures, including cleaning chemicals used, concentrations, and verification results, is essential for regulatory compliance and food safety audits.

Selecting Appropriate Cleaning and Disinfection Products

Choosing the right cleaning and disinfection products requires consideration of multiple factors including the target microorganisms, surface compatibility, contact time, and environmental impact. For healthcare settings, EPA-registered hospital-grade disinfectants with proven efficacy against relevant pathogens are essential. Food processing environments require food-safe sanitizers that don’t leave harmful residues. Surface compatibility is crucial—some disinfectants can damage certain materials over time. Contact time (the duration a surface must remain wet with disinfectant) varies significantly between products and targeted pathogens. Environmental considerations include VOC emissions, biodegradability, and potential respiratory irritation for users and occupants.

Cost Considerations and Provider Comparison

Implementing comprehensive cleaning, disinfecting, and sanitization programs involves significant investment in products, equipment, and training. Organizations must balance efficacy with cost-effectiveness when selecting solutions.

| Service Provider | Specialized Services | Key Features | Estimated Annual Cost (Medium Facility) |

|---|---|---|---|

| Ecolab | Healthcare and Food Industry Sanitation | Customized programs, Compliance monitoring | $15,000-$30,000 |

| Diversey | Medical Equipment Disinfection | Healthcare-specific solutions, Training programs | $12,000-$25,000 |

| STERIS | Advanced Sterilization Services | Validation services, Equipment maintenance | $20,000-$40,000 |

| 3M | Surface Disinfection Systems | Innovative application methods, Broad-spectrum efficacy | $10,000-$22,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Training and Compliance Requirements

Effective implementation of cleaning, disinfecting, and sanitization protocols requires comprehensive training programs and strict adherence to compliance requirements. Staff must understand the scientific principles behind these processes, proper chemical handling, appropriate PPE usage, and documentation procedures. Training should be role-specific, with different protocols for environmental services staff, clinical personnel, and food handlers. Regular competency assessments help ensure consistent application of protocols. Regulatory compliance varies by industry—healthcare facilities must adhere to CDC, OSHA, and accreditation standards, while food processing operations follow FDA and USDA guidelines. Documentation systems should track cleaning schedules, verification results, corrective actions, and training records to demonstrate compliance during inspections and audits.