Guide to Pursuing CNC Machinist Careers in Switzerland's Growing Industry

Switzerland's precision manufacturing sector offers promising opportunities for CNC machinists seeking international careers. The country's renowned engineering excellence and advanced manufacturing capabilities create a demanding yet rewarding environment for skilled professionals. From watchmaking to aerospace components, Swiss industries require exceptional precision and technical expertise that CNC machinists can provide.

Switzerland’s manufacturing landscape presents unique opportunities for CNC machinists looking to advance their careers in a precision-focused environment. The country’s commitment to high-quality production across various industries creates sustained demand for skilled machining professionals who can meet exacting standards.

Understanding the Role of a CNC Machinist in Switzerland

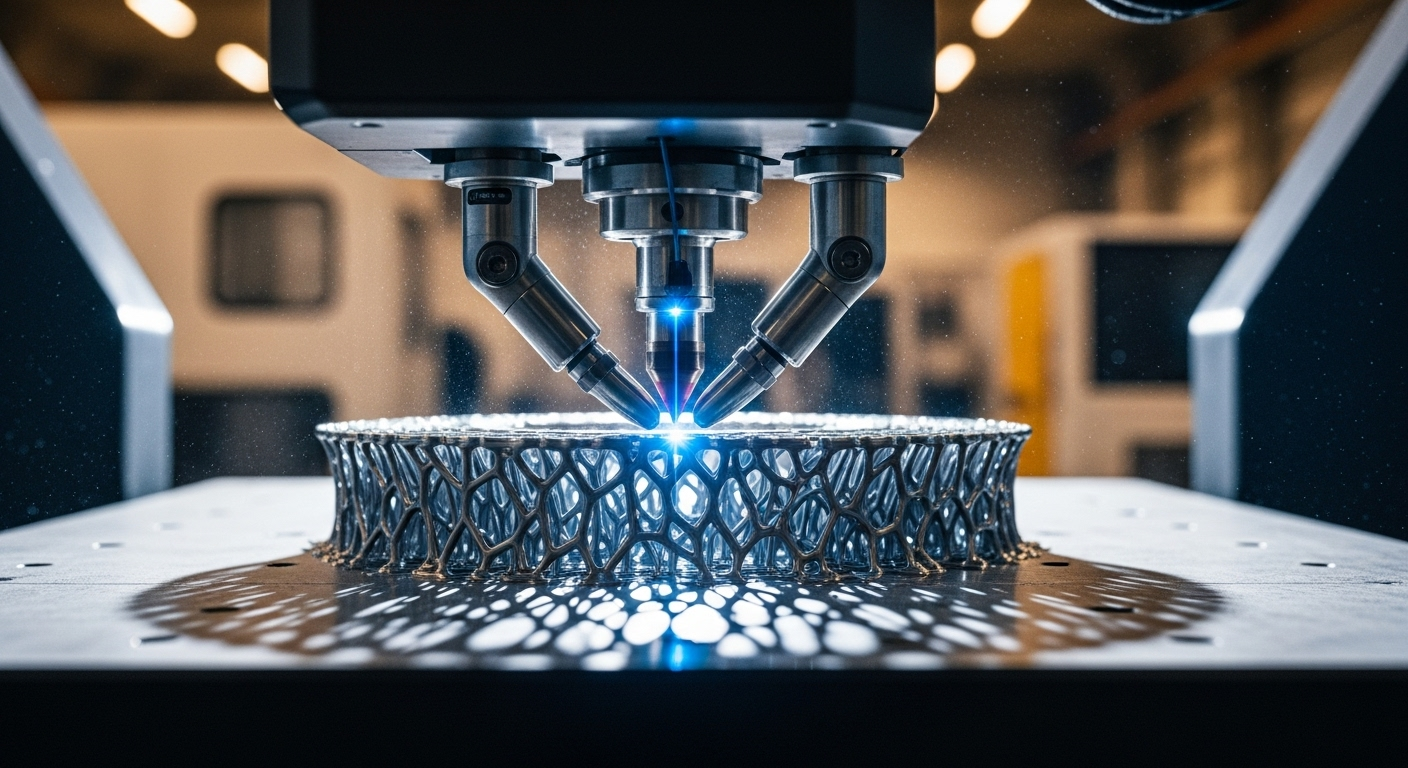

CNC machinists in Switzerland operate computer-controlled machine tools to produce precision components for diverse industries including watchmaking, medical devices, aerospace, and automotive manufacturing. These professionals interpret technical drawings, set up machines, monitor production processes, and ensure quality control throughout manufacturing cycles. Swiss employers typically expect machinists to work with tolerances measured in micrometers, reflecting the country’s reputation for precision engineering.

The role extends beyond basic machine operation to include programming, troubleshooting, and continuous improvement initiatives. Many Swiss companies integrate lean manufacturing principles, requiring machinists to participate in efficiency optimization and waste reduction programs.

Essential Skills for CNC Machinist Jobs

Successful CNC machinists in Switzerland must possess strong technical foundations including proficiency in CAD/CAM software, understanding of G-code programming, and familiarity with various machining materials from aluminum alloys to exotic metals used in specialized applications. Mathematical skills for calculating feeds, speeds, and tool paths are fundamental requirements.

Language capabilities significantly impact career prospects. While technical roles may accommodate English speakers, knowledge of German, French, or Italian depending on the region enhances communication with colleagues and supervisors. Many Swiss companies provide language training as part of professional development programs.

Problem-solving abilities and attention to detail are crucial given the precision requirements typical in Swiss manufacturing. Machinists must quickly identify and resolve issues while maintaining production schedules and quality standards.

Exploring Switzerland’s CNC Machining Industry

Switzerland’s machining industry spans multiple high-value sectors with distinct characteristics and requirements. The watchmaking industry, concentrated in the Jura region, demands exceptional precision for components often smaller than a fingernail. Medical device manufacturing requires strict adherence to regulatory standards and documentation procedures.

Aerospace and automotive suppliers focus on lightweight materials and complex geometries, while general precision engineering serves diverse industrial clients. Each sector offers different career trajectories and specialization opportunities for ambitious machinists.

The industry benefits from Switzerland’s central European location, providing access to major markets while maintaining the country’s reputation for quality and reliability. Many companies serve international clients, creating opportunities for machinists to work on globally distributed projects.

Opportunities and Challenges for CNC Professionals

Career advancement opportunities in Swiss machining companies often follow structured pathways from machine operator to programmer, setup specialist, or production supervisor. Many employers support continuing education and certification programs, recognizing that skilled workers drive competitive advantage.

Apprenticeship programs remain popular, combining classroom instruction with hands-on experience. These programs typically last three to four years and provide comprehensive training in machining fundamentals, Swiss quality standards, and industry-specific requirements.

Challenges include adapting to Swiss workplace culture, which emphasizes punctuality, precision, and systematic approaches to problem-solving. Cost of living considerations require careful financial planning, though competitive compensation packages often offset higher expenses.

Work permit requirements vary based on nationality and qualifications. EU citizens generally face fewer restrictions, while non-EU professionals may need employer sponsorship and must demonstrate specialized skills not readily available in the local labor market.

Building a Career as a CNC Machinist Abroad

Transitioning to Swiss employment requires thorough preparation including credential evaluation, language learning, and cultural adaptation. Professional certifications from recognized institutions enhance credibility with potential employers and may expedite work permit processes.

Networking through industry associations, trade shows, and professional organizations provides valuable connections and insights into job opportunities. Many Swiss companies prefer hiring through referrals and professional networks rather than public job postings.

Continuous learning remains essential as Swiss industries adopt advanced technologies including automation, robotics, and Industry 4.0 concepts. Machinists who embrace technological change and develop complementary skills position themselves for long-term career success.

| Provider/Program | Location | Key Features | Duration |

|---|---|---|---|

| Swiss Federal Institute for Vocational Education | Multiple Locations | Standardized apprenticeship programs | 3-4 years |

| Swissmem Training Centers | Various Cities | Industry-specific technical training | 6 months - 2 years |

| Regional Vocational Schools | Canton-based | Local employer partnerships | Variable |

| Private Training Institutes | Major Cities | Accelerated certification programs | 3-12 months |

Building a successful CNC machinist career in Switzerland requires combining technical excellence with cultural adaptability and continuous professional development. The country’s emphasis on precision manufacturing creates opportunities for skilled professionals willing to meet high standards while contributing to world-renowned Swiss quality. Success depends on thorough preparation, realistic expectations, and commitment to ongoing skill enhancement in an evolving technological landscape.