Metal Laser Welding Machines: A Comprehensive Guide

Metal laser welding technology has transformed manufacturing and fabrication processes across multiple sectors. These advanced machines use concentrated laser beams to join metal components with exceptional precision and minimal heat distortion. As industries demand higher quality welds and faster production cycles, understanding the capabilities, applications, and selection criteria for metal laser welding equipment becomes increasingly important for businesses and professionals seeking efficient joining solutions.

Metal laser welding represents a significant advancement in joining technology, offering manufacturers and fabricators a powerful tool for creating strong, precise connections between metal parts. This process harnesses focused laser energy to melt and fuse materials together, producing welds that often surpass traditional methods in quality and efficiency.

What Metal Laser Welding Machines Are and How They Work

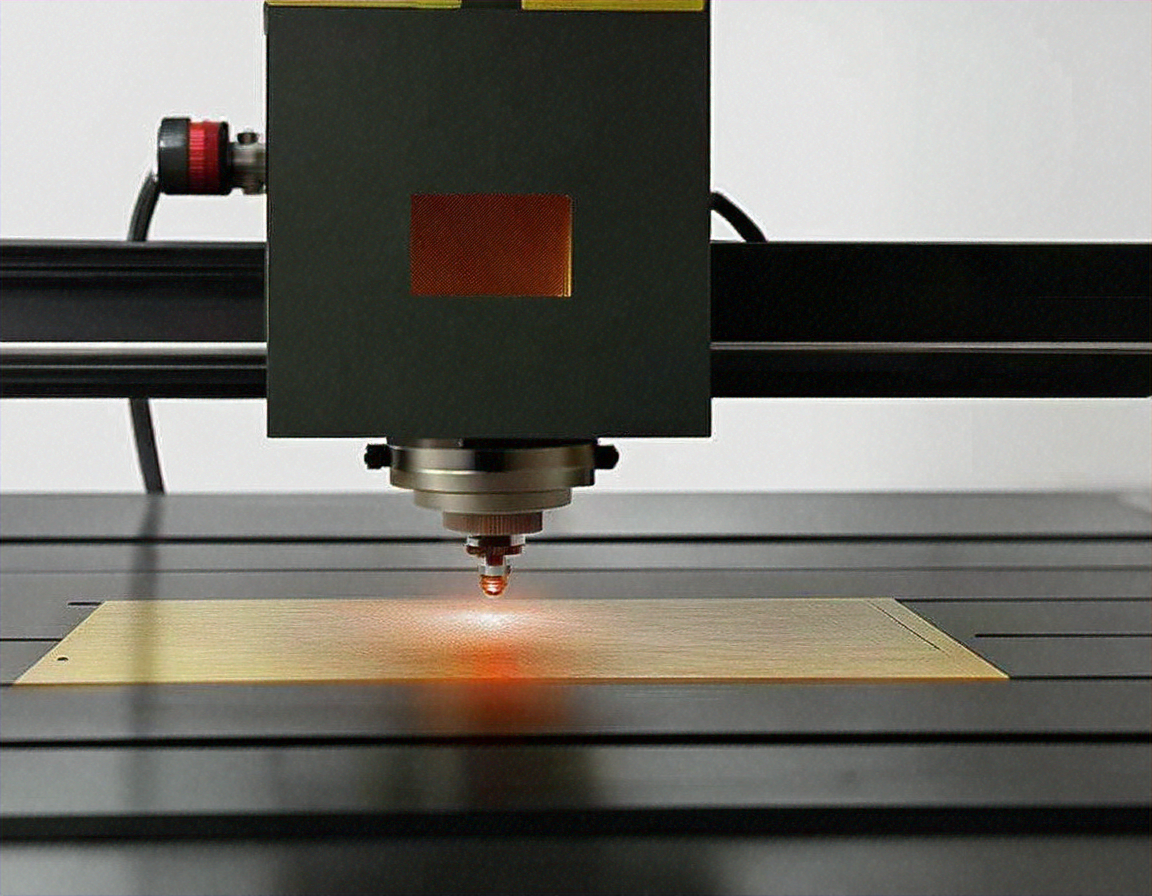

Metal laser welding machines generate an intensely focused beam of light that concentrates energy onto a small area of metal surface. The laser source, typically fiber, CO2, or diode-based, produces coherent light that travels through optical systems to reach the workpiece. When the laser beam contacts the metal, it rapidly heats the material to its melting point, creating a molten pool that fuses the pieces together as it cools.

The process can operate in two primary modes: conduction welding and keyhole welding. Conduction welding uses lower power densities to melt the surface, while keyhole welding employs higher intensities that vaporize material and create deeper penetration. Modern systems incorporate computer numerical control (CNC) technology, allowing operators to program precise weld paths and parameters. Protective gas, usually argon or nitrogen, shields the weld zone from atmospheric contamination during the process.

Key Benefits of Metal Laser Welding for Precision and Clean Results

The precision achievable with laser welding surpasses most conventional methods. The concentrated heat source creates narrow weld seams with minimal heat-affected zones, reducing distortion and maintaining the structural integrity of surrounding material. This characteristic proves particularly valuable when working with thin materials or heat-sensitive components.

Speed represents another significant advantage. Laser welding machines can complete joints much faster than traditional arc welding processes, increasing production throughput. The non-contact nature of the process eliminates electrode wear and reduces consumable costs. Additionally, the clean welds produced often require minimal post-processing, saving time and labor expenses. The ability to weld dissimilar metals and access hard-to-reach areas further expands the versatility of these systems.

Common Uses of Metal Laser Welding Across Industries

Automotive manufacturing relies heavily on laser welding for body assembly, transmission components, and battery pack construction for electric vehicles. The aerospace sector uses this technology for turbine components, fuel systems, and structural elements where weight reduction and strength are critical. Medical device manufacturers employ laser welding to create sterile, biocompatible joints in surgical instruments and implantable devices.

Electronics production utilizes laser welding for battery terminals, sensor housings, and microelectronic assemblies. Jewelry makers appreciate the precision for delicate repairs and custom fabrication. The oil and gas industry applies this technology to pipeline construction and repair, while shipbuilding operations use it for hull assembly and specialized components. Tool and die making, precision instrument manufacturing, and consumer goods production also benefit from laser welding capabilities.

How to Choose a Metal Laser Welding Machine

Selecting appropriate equipment requires careful consideration of several factors. First, identify the materials you will weld, including their types, thicknesses, and joint configurations. Different laser sources excel with specific materials—fiber lasers work well with reflective metals like aluminum and copper, while CO2 lasers suit thicker steel applications.

Power output determines penetration depth and welding speed. Applications involving thin materials may require only 500 to 1000 watts, while heavy industrial use might demand 3000 watts or more. Evaluate the work envelope size to ensure it accommodates your largest components. Consider whether you need a handheld system for flexibility or a fixed automated station for repetitive production.

Additional features to assess include cooling systems, beam delivery methods, control software capabilities, and safety features. Integration with existing production lines, maintenance requirements, and availability of technical support should also influence your decision. Training resources and ease of operation matter, especially if multiple operators will use the equipment.

Cost Factors and Where People Commonly Buy These Machines

Investment in metal laser welding equipment varies significantly based on specifications and capabilities. Entry-level handheld systems suitable for small workshops or repair operations typically range from 5,000 to 15,000 USD. Mid-range automated systems with moderate power outputs generally cost between 30,000 and 80,000 USD. High-power industrial systems with advanced automation and large work envelopes can exceed 150,000 USD, with some specialized configurations reaching 300,000 USD or more.

| System Type | Typical Power Range | Cost Estimation (USD) | Common Applications |

|---|---|---|---|

| Handheld Portable | 1000-2000W | 5,000-15,000 | Repairs, small fabrication |

| Desktop Automated | 500-1500W | 15,000-40,000 | Jewelry, electronics, medical devices |

| Industrial Fixed | 2000-4000W | 50,000-150,000 | Automotive, aerospace, manufacturing |

| High-Power Production | 4000W+ | 150,000-300,000+ | Heavy industry, large-scale production |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Buyers typically acquire these machines through specialized industrial equipment distributors, directly from manufacturers, or through authorized regional dealers. Many companies purchase from established brands with global presence and comprehensive support networks. Online marketplaces have emerged for smaller systems, though buyers should verify seller credentials and warranty terms. Leasing and financing options are commonly available for larger investments. Trade shows and industry exhibitions provide opportunities to compare models and negotiate with multiple vendors.

Understanding the Long-Term Value

Beyond initial purchase price, consider operating costs including electricity consumption, consumables, maintenance, and potential downtime. Quality systems from reputable manufacturers often justify higher upfront costs through reliability and lower long-term expenses. Warranty coverage, availability of replacement parts, and technical support responsiveness significantly impact total cost of ownership. Training programs help operators maximize equipment potential and reduce errors that could damage components or produce defective welds.

Metal laser welding machines represent sophisticated tools that deliver exceptional results when properly selected and operated. By understanding the technology, evaluating your specific requirements, and carefully comparing available options, you can make informed decisions that enhance your production capabilities and deliver strong returns on investment.